Innovative Ceramic Micro Heatsinks

Optimized Cooling Solutions for Space-Constrained Applications with Tailored Designs and Zero Tooling Expenses

Advanced electronics and photonics applications require efficient thermal management. As electronic devices continue to shrink in size while increasing in power, the need for effective cooling solutions becomes more pressing. Our innovative ceramic micro heatsinks leverage favorable ceramic materials properties, cutting-edge zero-tooling manufacturing processes and precision engineering. These heatsinks offer unparalleled performance in compact and confined spaces.

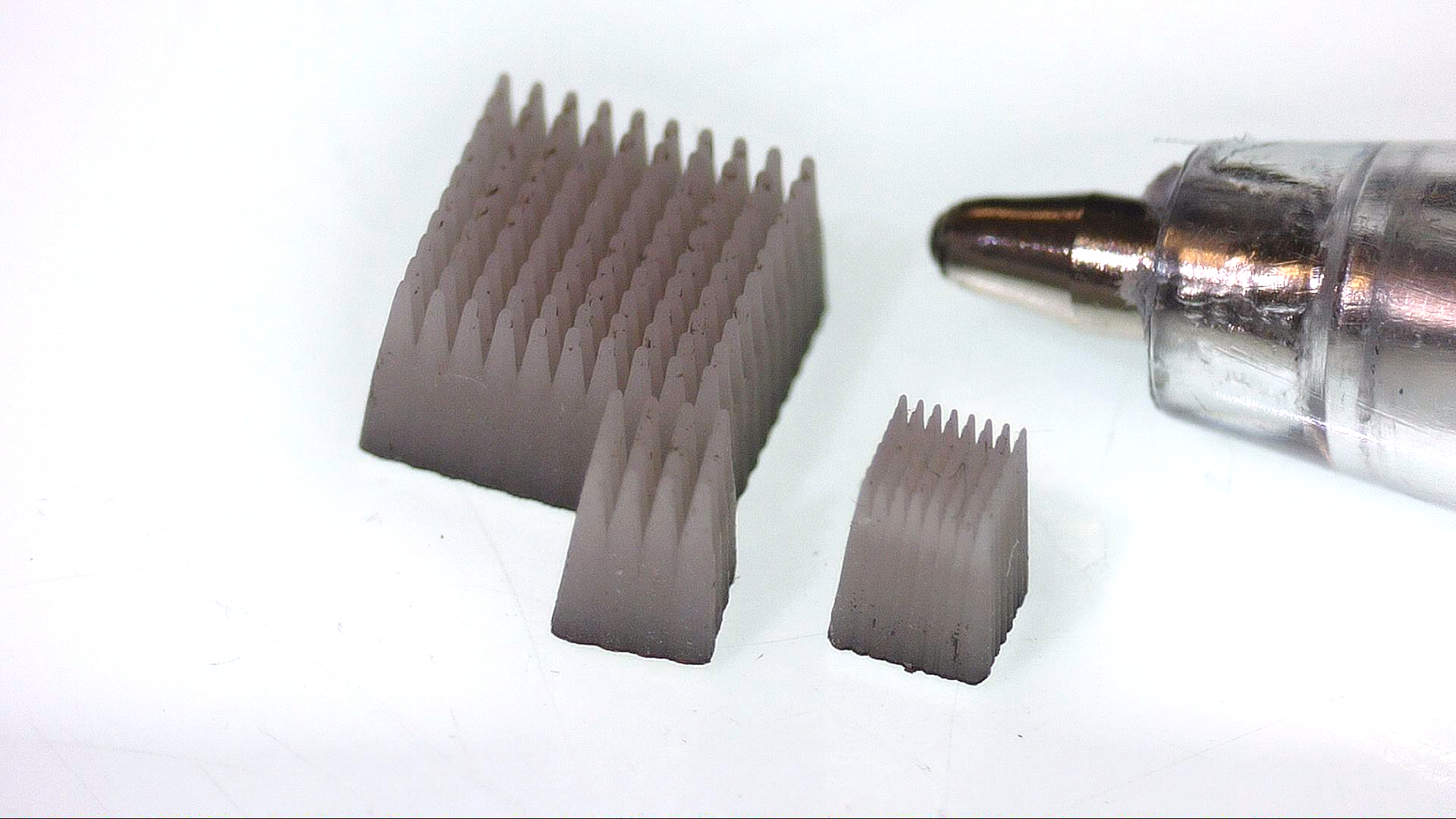

Example of a 5x5x3mm micro AlN heatsink with 0.25mm dia pins in a 0.5mm pitch

Harness the cooling power of Ceramics

Our ceramic micro heatsinks are typically made from aluminum nitride (AlN), known for its excellent thermal conductivity and electrical insulation properties. This material choice ensures that the heatsinks can effectively dissipate heat while maintaining electrical isolation, making them ideal for sensitive electronic applications. Additionally, we offer options in aluminum oxide (Al2O3) and silicon nitride (Si3N4) to cater to diverse application needs, providing flexibility in material selection based on specific thermal and mechanical requirements.

The design of our ceramic micro heatsinks focuses on maximizing surface area to enhance cooling efficiency. By incorporating intricate patterns and structures, we can significantly increase the surface area available for heat dissipation, allowing for more effective thermal management in even the most confined spaces. This makes our heatsinks particularly suitable for applications where space is limited, but efficient cooling is essential.

Benefits

- Efficient Cooling: Designed to increase surface area and enhance cooling efficiency for components in confined spaces.

- Versatile Applications: Ideal for microelectronics, Laser & LED lighting, medical devices, telecommunications, and automotive industries.

- Thermally conductive, electrically isolating: Provides effective thermal management for sensitive and high-performance components without stray capacitance build up.

Flexible & customizable

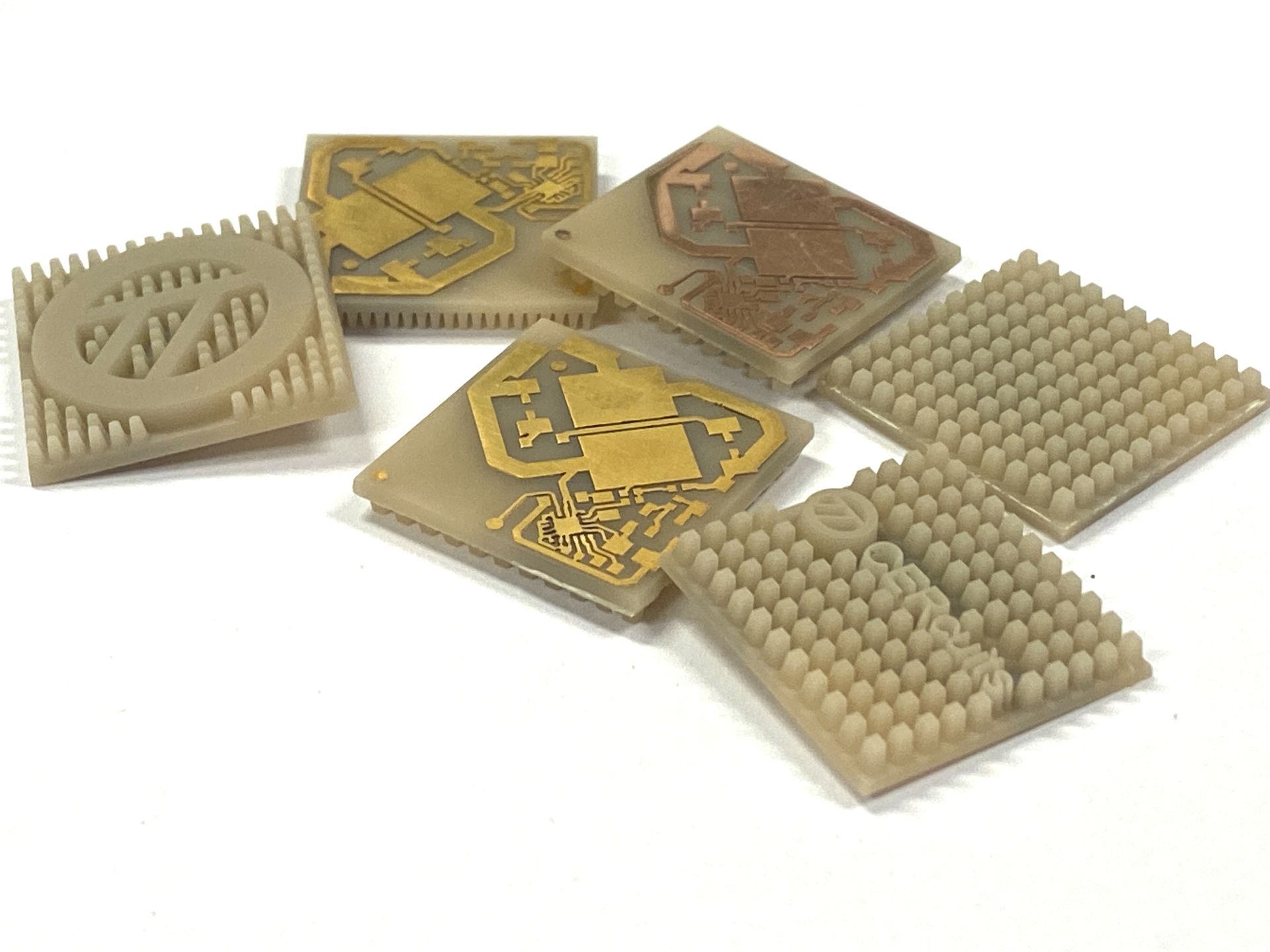

Our heatsinks are not only designed for performance but also for versatility. They can be provided with a metal backing, allowing for easy soldering onto other surfaces, or without a metal layer for gluing with thermal adhesive. This flexibility in mounting options ensures that our heatsinks can be seamlessly integrated into a wide range of applications. Furthermore, the option to create circuits on the flat side of the heatsink adds an additional layer of functionality, enabling more complex and integrated thermal management solutions.

Design Features:

- Available in sizes as small as 2x2mm with pins as small as 0.1mm in diameter at the tip.

- Thickness Options: Thickness can range up to 5mm, with options as thin as 1mm.

- Can be provided with a metal backing for soldering onto surfaces, or without a metal layer for gluing with thermal adhesive. Ceramic is also compatible with brazing.

- Circuit Integration: Option to create circuits on the flat side of the heatsink, rather than just a single metal area.

- Pins, fins, cubes,... or any other shape

A 2x2x3mm heatsink with 0.1mm dia pins and 0.2mm pitch

One-off customized heatsinks 20x20mm with a electronic circuit on the backside.

No tooling costs & Min. Order Qty 1

At CERcuits, we pride ourselves on our ability to customize each part to meet specific requirements. Whether you need a unique design, a specific material, or a particular mounting option, we can tailor our heatsinks to suit your needs. We do not charge any tooling costs for manufacturing these heatsinks, and our minimum order quantity is just one piece, making our solutions accessible and cost-effective.

Additionally, our short lead times ensure that you receive your heatsinks promptly, provided we have the material in stock.

Some questions you might have

We are working on them but since this is a highly customizable product it is not an easy task to pour into standard rules. The easiest way to move forward is to contact us and we can check you design.

In addition, below are a few ground rules from designs we already made

- Size: The smallest heatsink is 2x2mm, largest 20x20mm but in theory it can go up to 100x100mm. Heatsinks do not need to be square and can be virtually any shape

- Height / thickness: So far, we made up to 5mm thick and the thinnest was 1mm with pins of 0.8mm.

- Pin/fin/block... diameter/width and pitch: we have made 0.1mm diameter pins that were spaced 0.1mm apart on a 3mm high heatsink. We might be able to shrink that but this will reduce the height that the features can be. Also note that the higher and thinner the features, the more taper they will have. Typically the taper is 5 degrees but this can vary from design to design.

- Materials: AlN is our standard micro heat sink material but we can also make them in Alumina (Al2O3) or Silicon Nitride. We also have done some test on Silicon Carbide (SIC) which were successful. Even though Alumina is a cheaper material then f.e. AlN, machining it, is harder so we recommend to use the better material as the price difference might be minimal despite lower material costs.

- Circuits: making an electronic circuit can be done on the flat side of the heatsink... or not. We can also create fins or pins or other features around a component in stead of on the opposite side (or both sides)

Ceramic micro heatsink pricing cannot be compared to common metal heat sinks. The process and materials are entirely different and they typically serve a different purpose. It makes no sense to use a ceramic micro heatsink if a standard metal heatsink is possible in the applications. However, if you applications cannot work with standard metal heatsinks and you would like to control the price. Here are a few pointers.

- Ceramic micro heat sinks are made from a substrate or block where material is machined away. So to optimize costs, making dense pin/fin configurations results in less material to be removed and less machining time.

- Making pins/fins down to 0.5mm with 0.5mm space is fairly standard but bringing the width & pitch further down will decrease the manufacturing speed and increases the costs. However, this might reduce the size of your design allowing us to make more parts from one block. So bringing size down will improve costs up to a certain limit in regards to feature size.

- Even though Alumina is a cheaper material then f.e. AlN. Machining it is harder so we recommend to use the better material as the price difference might be minimal despite lower material costs. Only for higher volume applications the material costs might become more relevant.

- Standard we have most Aluminium nitride thickness on stock up to 3mm and Alumina up to 2mm. We also have silicon nitride and silicon carbide up to 1mm.

Micro heat sinks, particularly those made from ceramic materials, offer several advantages over traditional metal heat sinks. They provide a greater surface area for heat dissipation, which can be up to 30% more than metal heat sinks. This results in better heat convection properties and reduced thermal resistance.

Additionally, ceramic micro heat sinks help minimize electromagnetic interference (EMI) issues due to their non-metallic nature.

They are also resistance to most environmental hazards and do not rust or degrade.

Last but not least, the thermal expansion of ceramic materials are typically much lower then metals resulting in lower thermo-mechanical stress .

Our ceramic micro heat sinks are designed to last the lifetime of the electronic device they are integrated with, ensuring long-term reliability. Ceramic materials typically do not degrade in any of the environmental conditions that are typical for electronics assembly. In case you have a specific case (temperatures above 1000C, high acidic environment, high pressure, ... ), please reach out and contact us to discuss.

Ready to enhance your thermal management solutions with our ceramic micro heatsinks?

Contact us today via sales@cercuits.com or via the form below to discuss your specific requirements and get started on your order